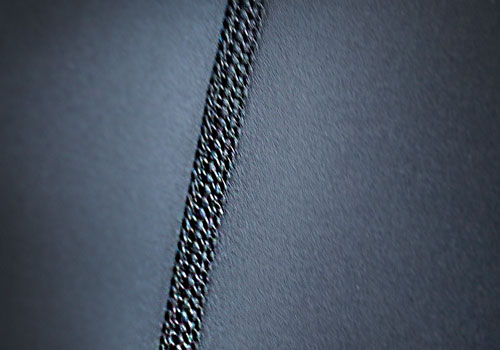

Flat Lock Seams

The seams are one of the core features of a wetsuit. They determine the strength, flexibility and watertightness of its construction, so it's an important factor when picking the right suit for you.

GBS Seams

A GBS seam is glued together with waterproof glue then blind stitched together. The stitch only passes half way through the neoprene. The result is a durable waterproof seam that keeps water out. Some manufacturers use double and triple gluing techniques as well as doubling the blind stitch, this reinforces the seams and makes them extremely durable.

Fluid & Liquid Seams

A durable liquid rubber that seals GBS (Glued & Blind Stitched) seams. This liquid rubber can be applied internally, externally or both. The advantage over a GBS seam is that the Fluid Seam is typically the most watertight seam. There are different types of Liquid / Fluid seams. Some are thinner, lighter, and more Flexible than others.

Fused/Welded Seams

Fused / Welded Seams are extremely durable, stitch-free, and typically provide maximum stretch in all directions. Each manufacture names this type of seam differently. The key differentiate is that these seams are cypher and use less rubber giving them a lower profile.

Taped Seams

Taped Seams can be applied over the interior or exterior the seams. These are typically super stretchy and add extra durability and comfort. Higher end taped seams are more flexible and water resistent than other less expensive taped seams.

Spot Taping

Spot tape is used to help prevent leaks or tears at the intersections and stress points of your wetsuit. Spot taping is also used to strengthen the seams within your wetsuit. Spot taping is typically used in conjunction with glued and blindstitched seams create seams that are high performance and almost indestructible.